Scraper Film Evaporator

Overview WFE:

GXZ Rotary scraper film evaporator is a film by rotating scraper force can be carried out under vacuum conditions, evaporation of falling film evaporator of new and efficient. It is heat transfer coefficient, evaporation, high strength, short time overcurrent, operating flexibility, particularly suitable for heat-sensitive materials, high-viscosity materials and materials containing particles crystallize evaporation, degassing desolventizing, purified by distillation. Therefore, in the chemical, petrochemical, pharmaceutical, pesticide, cosmetic, food, fine chemical industry is widely available.

My company has been manufacturing such equipment more than ten years, has accumulated rich experience in manufacture and use. Over the years, according to market demand closely with the user's actual production to meet the technological requirements of the user's premise, choose the appropriate device structure, to ensure superior quality and reliable manufacturing, the tooling equipment, testing methods and product design in areas such as improving and maturing, and achieved remarkable results, level of technology and product quality at the leading level in China.

Scraper structural characteristics of thin-film evaporator:

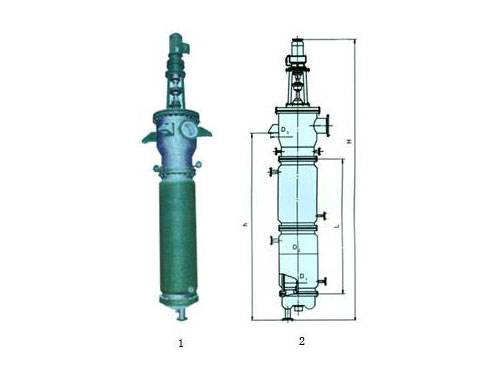

LG Series film evaporator as shown in Figure 2 the main structure, the structural parts are as follows:

1 motor, reducer: it is the rotation of the rotor drive. Rotation of the rotor speed will depend on the scraper from the form. The material viscosity and evaporation Flashlight diameter; choose the appropriate speed scraper is to ensure stable and reliable operation of the evaporator and the satisfactory results of the important parameters of evaporation.

2 separate tube: material from the body of the barrels in separate entrance cut into the bottom of the evaporator, and were installed in the distributor separation Flashlight is evenly distributed in a continuous inner wall evaporation, evaporation from the evaporation Flashlight out Steam rose from the second separation cartridges, including installation of gas-liquid separator, the secondary steam-carrying droplets or bubbles may separate, secondary steam from the top of the exit leads to the evaporator. Resistance in the evaporator based on the separation of the calculation Flashlight rational design is to avoid material "short" one of the key factors. (So-called "short circuit" means the material entered the evaporator, the evaporation process has not been completed, exit from the secondary steam evaporator.)

3 distributor: fabric mounted on the rotor. Rational design, the direction from the tangent of the material into the evaporator, by rotating the distributor, is continuously poured membrane was evenly distributed in the evaporation surface.

4 gas-liquid separator: rotary vane-type gas-liquid separator installed in the top of the separation barrel, it will rise in the second steam-carrying droplets or bubbles may trap and make it down to the evaporation surface.

5. Evaporative Flashlight: Flashlight, also known as heat. It is compulsory rotating scraper film material and the jacket of the heating medium for heat exchange surface evaporation. Flashlight diameter and length of the evaporation from the evaporation area and determine the appropriate aspect ratio. Heated inner wall by special machining and polishing, and one with both ends of the flange face on the process and ensure the equipment as a whole circle degrees. Polished (mirror polished if necessary) of the inner wall smooth and clean bright, easy to stick materials and scale, effectively ensuring the equipment of high heat transfer coefficient.

WFE Performance characteristics:

Thin-film evaporator has the following unique advantages, conventional film evaporator can not be compared:

1 small pressure loss in the rotating scraper film evaporator, the material "flow" and the secondary steam "flow" are two separate "channels": the material along the cylinder wall evaporation (forced film) falling film down; by the evaporation of surface evaporation of the secondary steam from the central cylinder of space almost unimpeded to leave the evaporator, the pressure loss (or pressure drop) is very small. This

2 can be true under the conditions of operation of a vacuum: is due to the secondary steam from the evaporator to the condenser surface resistance is extremely small, so make the whole wall of the evaporation surface evaporation tube to maintain a high vacuum (up to-750mmHg above ), almost equal to the vacuum system outlet vacuum. As the vacuum of the increase, effectively reducing the boiling point of the material being processed.

3 high heat transfer coefficient, high evaporation strength: the lower boiling point materials, increases with the heat medium temperature difference; was a turbulent liquid film, reducing the thermal resistance; Similarly, inhibition of the material in the wall of coke, fouling, and increased evaporation of the sub-cylinder wall heat transfer coefficient; efficient rotary film evaporator overall heat transfer coefficient up to 8000KJ / h • m • ℃, so the evaporation intensity is high.

4 low-temperature evaporation: evaporation tube body to maintain high vacuum, the boiling point of the material being processed greatly reduced, making it ideal for low-temperature evaporation of heat sensitive materials.

5. Overcurrent time is short: the material in the flow over the evaporator is very short, less than 10 seconds; scraper for common activities, its animal feed scraping the end of a diversion trench (see Figure 5 ), the angle is usually 45 °, to change the bevel angle can change the flow of materials over time, the material in the scraper scraping action, the spiral down to leave the evaporator. Reduce over-current time, to effectively prevent product decomposition during evaporation, aggregation, or deterioration.

6 can use low-grade steam: Steam is commonly used in hot medium, the boiling point due to the reduction of materials, ensuring the same Δt conditions, can reduce the heating medium temperature, the use of low-grade steam, is conducive to the comprehensive utilization of energy . Particularly suitable as a multi-effect evaporation of the end-effect evaporator.

7. Adaptability, easy to operate: a unique design, so that the product can be difficult to deal with some of the conventional evaporator handle high viscosity, including particles, heat-sensitive and easy to crystallize the material. Rotary film evaporator operating.

Print this Page

Print this Page

Add to Favorites

Add to Favorites

Skype Online

Skype Online

Email

Email

PDF DownLoad

PDF DownLoad