Product application:

The filter filter for filtering milk, sugar, beverages, glue, liquid and other liquid herbal compound fine particles of various types of impurities. Two cartridge filters can be simultaneously or alternately, non-stop to replace the filter, especially suitable for continuous production. With the pollutant carrying capacity, fast filtration rate, low cost, easy to operate.

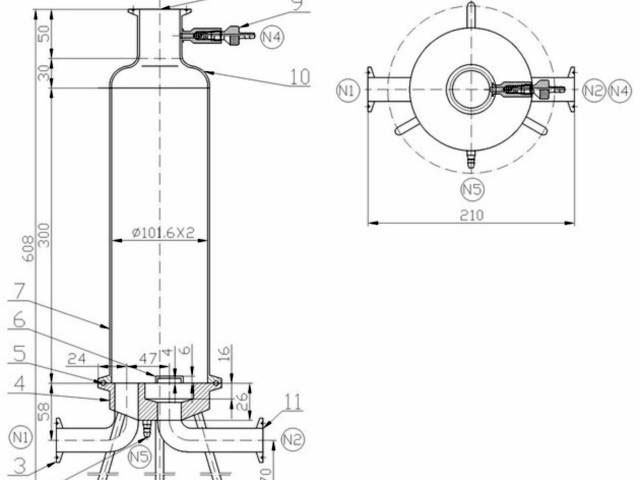

Structural features: This filter consists of two cylindrical tube formed with the connecting pipe, inside and outside surfaces polished, stainless steel filter cartridge that has the support basket and filter; top with release valve for the filter within the filter when the emissions air role. Connection with the cartridge cover with quick-open structure, more convenient and clean (replace) the filter, three adjustable feet enable smooth filter placed on the ground. The loose connection or a connection clamp pipe connection, the use of butterfly valves open and close access to materials, pressure temperature, convenient operation, no liquid leak is more hygienic.

Usage:

1, thoroughly clean the filter and filter connected components, properly installed the filter and housing.

2, first check the pressure before starting the pump is clockwise, check closely connected, the valve is closed.

3, before starting to slowly open the inlet valve first, through the exhaust, then open the valve to normal filtration.

4, filter found more than 0.1Mpa pressure difference or flow decreased significantly, indicating that the filter has blocked most of the aperture, advise clients on the filter for cleaning or replacement.

This series of stainless steel micro-filter to filter out most of the particles, so widely used in fine filtration and sterilization processes.

■ cartridge has a core, 3 core, 5-pin, 7 pin, 9-pin, 11-core, 13 core, 15 core

■ folded filter length 10, 20, 30, 40

■ filter materials are polypropylene, PTFE, cellulose acetate

■ filter pore size are: 0.1um, 0.22um, 1um, 3um, 5um, 10um

■ sub-hydrophobic (for gas) and hydrophilic (for day liquid) filter, may need to use.

Features & Applications:

Microporous filter element: polypropylene film (PP) filter, PTFE (PTFE) filter, cellulose acetate membrane (CN - CA) filter, filtration from 0.1-60um, length 10; 20 ; 30 and 40 inches (250; 500; 750; 1000mm) four, the filter, pressure to 0.42mpa, to recoil. Interface with plug-in (222, 226 two kinds of) peace mouth type two kinds.

Technical parameters:

■ filtration capacity T / H: 0.05-20

■ filter using pressure mpa: 0.1-0.6

■ the number of filter core machine specifications: 1,3,5,7,9,11,13,15

■ filter temperature ° C: 5-55

■ Filtration (um) :0.1,0.2,0.45,1-60

■ filtration capacity (t / h) :0.5-100

■ filter length (m / m) :250-1000

■ Working pressure (Mpa) :0.1-0 .6

■ cartridge has a core, 3 core, 5-pin, 7 pin, 9-pin, 11-core, 13 cores, 15 cores, 21 cores, 32 cores

■ folded filter length 10, 20, 30, 40

■ filter materials are polypropylene, PTFE, cellulose acetate

■ filter pore size are: 0.1um, 0.22um, 1um, 3um, 5um, 10um

Print this Page

Print this Page

Add to Favorites

Add to Favorites

Skype Online

Skype Online

Email

Email

PDF DownLoad

PDF DownLoad